A1-3.超級切碎機 Super Chopper

A1-3.超級切碎機 Super Chopper

A1-3.超級切碎機 Super Chopper

A1-1最好的廢輪胎回收THE BEST OF TYRE RECYCLING 下載down load

最好的選擇THE BEST CHOICE

A1-2

廢輪胎回收工廠和機器TYRE RECYCLING PLANTS AND MACHINES

為了完成最終產品所需要的形式 ,可以使用不同標準的輪胎回收工廠, 這些標準工廠起始點在於此種工廠,能適合特別規格客戶需求而訂製

To achieve the required type of end-product, different standard tyre recycling plants are available. these standard plants are also the starting point when plants are tailored to suit specific customer requirements.

使用模組型完成,有很多組合能被提供來生產碎片、碎渣、粒狀物和粉狀

Using a modular approach, a large number of combinations can be supplied to produce shreds, chips, granulate and power.

保證的技術PROVEN TECNNOLOGY

本設備設計符合市場需求

這些個別機能很容易被調整到其他部份之尺寸,只要改變機器上篩網尺寸即可

The equipment is designed to meet market requirements, thus the individual machines can easily be adjusted to other fraction sizes, merely by changing the screen size in the machines.

A1-3

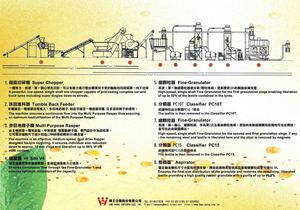

1.超級切碎機Super Chopper

一種有力、低速、單一軸心預先切碎,可以有能力進行整台轎車和卡車的輪胎包括超級單一向下切碎

A powerful, low-speed, single shaft ore-chopper capable of processing complete car and truck tyres including super singles down to shreds.

2.跌回進料器Tumble Back Feeder

本機確定一種連續流程進入,多目地的銼子,如此可確定一種適當荷重/及多目的銼子的使用

The machine ensures a continuous flow into the Multi Purpose Rasper thus ensuring an optimum load/utilization of the Multi Purpose Rasper.

3.多目地銼子機Multi Purpose Rasper

此支機器是一種有效益,中等速度,雙驅動銼子器, 專門設計作為回收用,它可確定個別尺寸減少到約12MM碎屑和釋放98%鐵含量

The machine is an effective, medium-speed, dual drive Rasper designed for tyre recycling. It ensures individual size reduction down to approx. 12 mm chips and liberation up to 98% of the steel content.

4.儲藏槽V4 SILO V4 Silo V4

確定連續流程經過細顆器,並確認適當能力之使用

Ensures continuous flow through the Fine-Granulator 1 and ensures optimum utilization of the capacity.

5.細顆粒器Fine-Granulator

高速,單一軸細顆粒器適合第1顆粒等級,使其釋放50%的輪胎紡織含量

High-speed, single shaft Fine-Granulator for the first granulation stage enabliog liberation of up to 50% of the textile contained in the tyres.

6.分類器PC10T Classifier PC10T

紡識物在此分類器PC10 T移去The textile is then removed in the Classifier PC10T.

7.細顆粒器Fine-Granulator

高速、單一軸心, 細顆粒器, 作為第2次及最後顆粒等級

假如尚有餘留鋼鐵和紡織物可在此釋放,並可在此由磁鐵釋出

High-speed, single shaft Fine-Granulator for the second and final granulation stage. If any - the remaining steel and textile is liberated here and the steel is removed by magnets.

8.分類器PC15 Classifier PC15

紡織物可從PC15分類器移去The textile is then removed in the Classifier PC15.

9.粗糙器Aspirator

確定最後顆料尺寸分配和移開多餘,釋放紡織物而提供高品質橡膠顆粒純度可達99.9%

Ensures the final size distribution of the granulate and removes the remaining, liberated

textile providing a high quality rubber granulate with a purity of up to 99.9%.

A1-4

特性Features

·高性能High performance

·多用途以製作不同的輸入材料Flexibility to process different input materials

·多用途以製作不同的輸出材料Flexibility to process different output materials

·乾淨顆粒可達99.9%不含鐵絲和紡織物 ( ASTM-E11 或DINISO3310 )

Clean granulate up to 99.9% free of liberated steel and textile (ASTM-E11 or DIN ISO 3310)

·低製作成本Low processing costs

·低電力請耗Low power consumption

·低維修成本Low maintenance costs

售後服務可確信減少當機時間After sales service ensure reduced downtime

售後服務部門是您可信賴伙伴The After Sales Division is your reliable partner!

·售後服務部門提供了AD.HOC服務,對於現有和新設備,經過訓練有素和經驗豐富的工程師和監督者

The After Sales Division offer ad hoc service on existing as well as new equipment through our trained and experienced service engineers and supervisors.

·通常保持廣泛的存儲備品和消耗器We constantly hold an extensive stock of spare and wear parts.

·機動性服務合約確定有計劃性 ,可防止生產線上維修

The flexible service contracts ensure planned, preventive maintenance of your production line.

·個案合約,可確保零件不缺作為緊急使用

Tailored contracts ensure that parts are available for immediate call off.

·只要連絡我們備品和消耗品人員之一,我們特提供是好可能解決方案

Contact one of our spare and wear part coordinators, and we will supply the best possible solution for your

company.

A1-5

選用模組作為特定客戶之需求用Optional modules for specific customer requirements

·轎車輪胎進料器Car Tyre Feeder

進給能力5-6T/生產小時,此進料器為自動的確定可連續的進料給超級切碎機,傾倒效益可減少輪胎外體的含量

Feeding capacity 5-6 ton/production hour. The feeder automatically ensures continuous feeding of the Super Chopper. The tumbling effect reduces the content of foreign in the tyres.

·鋼材清潔系統Steel Cleaning System

減少在鐵的部份橡膠和紡織物含量減到1-2%(98-99清潔鋼絲)以重量計

Reduces the rubber and textile content in the steel fraction down to 1-2% (98-99% clean steel wire), by weight.

·品質提升系統Quality Upgrading System

橡膠粒主要部份之最大純度為99.99%(以重量計)清潔”黑金”不含石頭、金屬、玻璃和其他不純物

Ultimate purity of the main fraction of rubber granulate = 99.9% by weight, clean “Black Gold” free of stones, metals, glass and other impurities.

·破碎機系統Cracker Mill System

適合客戶和市場需求粉狀物可達2500-50網

Meets customer and market demands for powder down to 200-50 Mesh.

·裝袋系統Bagging System

使用袋子作為尾端產品,本公司提供單一和多袋站秤重和秤量系統

Used for bagging of the end-product. We offer single and double bagging stations, Weighing and scaling equipment is also available.