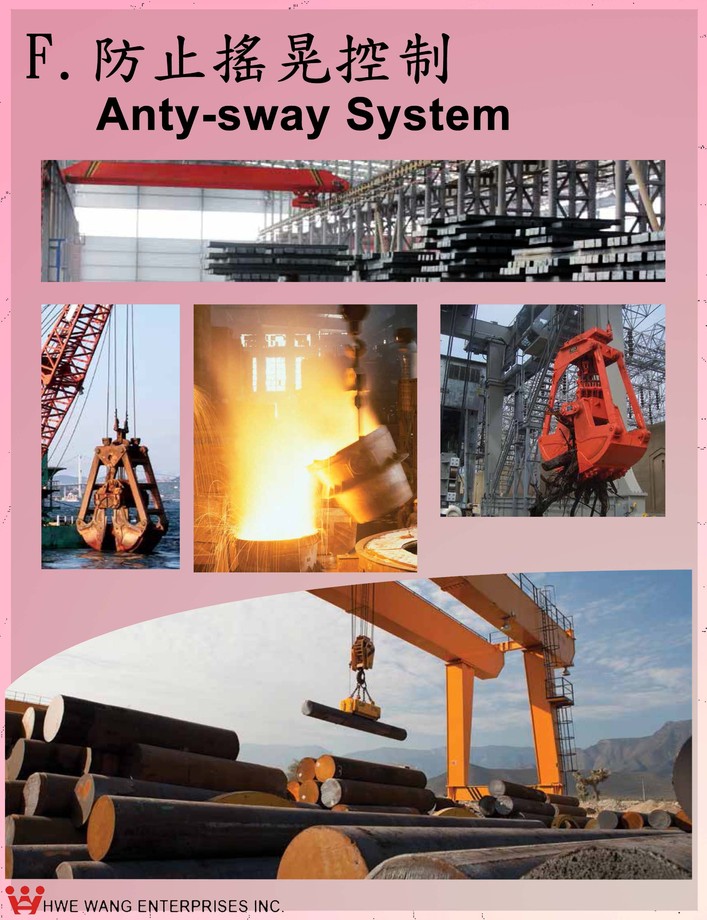

F.防止搖晃控制

Anti-Sway System

1.S3變頻器 2.搖晃控制系統 3.抓斗控制軟件

IMPULSE G+/ VG+ SERIES 3 DRIVES Sway Control System Bucket Control Software

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 下載down load

IMPULSE G+/VG+ SERIES 3 DRIVES CUSTOM SOFTWARE APPLICATIONS

1-1.腳踏剎車/靜態無段式模擬軟體 FOOT BRAKE / STATIC STEPLESS SIMULATION

SOFTWARE

變頻同步軟體DRIVE SYNCHRONIZATION SOFTWARE

抓斗控制軟體BUCKET CONROL SOFTWARE

防止搖晃控制系統(SCS) S2 SWAY CONTROL SYSTEM (SCS) SERIES 2

1-2.防止搖晃控制系統(SCS) S2

SWAY CONTROL SYSTEM (SCS) SERIES 2

使用MAGNETEK防止搖晃系統來加強天車操作

ENHANCE CRANE OPERATION WITH MAGNETEK’S SWAY CONTROL SYSTEM

SCS SERIES 2好處 SCS SERIES 2 BENEFITS

SCS SERIES 2被設計成 SCS SERIES 2 HAS BEEN DESIGNED TO

性能特性-包括項目 PERFORMANCE FEATURE INCLUDE

1-3.腳踏剎車/靜止無段式模擬軟體

FOOT BRAKE / STATIC STEPLESS SIMULATION SOFTWARE

客戶使用腳踏剎車/靜止無段模擬軟體

CUSTOM FOOT BRAKE / STATIC STEPLESS SIMUATION SOFTWARE

使用此軟體到 APPLY THIS SOFTWARE TO

靜態無段模擬軟體 THE STATIC SEPLESS SIMULATION SOFTWARE

1-4.變頻器同步軟體 DRIVE SYNCHORIZATION SOFTWARE

多個變頻器需要同步 , IMPUSE變頻器同步軟體能容易做到

NEED TO SYNCHRONIZE MULTIPLE DRIVES OUR IMPULSE? DRIVE

SYNCHRONIZATION SOFTWARE MAKES IT EASY

你能 YOU CAN

這個新變頻同步軟體 THIS NEW DRIVE

變頻器同步軟體可以使用在 DRIVE SYNCHRONIZATION SOFTWARE MAY BE APPIED ON

1-5.抓斗控制軟體 BUCKET CONTROL SOFTWARE

使用我們抓斗控制軟體可節省時間和金錢

SAVE TIME AND MONEY WITH OUR BUCKET CONTROL CUSTOM SOFTWARE

APPLICATION

2.搖晃控制系統 Sway Control System 下載down load

2-1.搖晃控制系統系列2 IMPULSE Sway Control System Series 2

改造安裝 Retrofit Installations

使用MAGNETEK IMPULSE 搖擺控制系統加強天車操作

Enhance Crane Operation With MAGNETEK'S IMPULSE Sway Control System

Magnetek IMPULSE 搖擺控制系統(SCS)系列2訂製軟體能加到任何品牌現有大車和小車上可

變速度的變頻器。外部改造系統提供了現有天車安裝上搖擺控制系統的優點。

Magnetek IMPULSE Sway Control System(SCS) Series 2 custom software can be added to

any brand of existing bridge or trolley variable speed drives. This external retrofit system

provides the benefit of sway control on an existing crane installation.

增加安全和性能 Improved Safety and Performance

-藉著允許天車控制者在全速時移動荷重物而且停止時勿需等待荷重搖擺的損失而改進產能。

Improves productivity by allowing the crane operator to move loads at full speed and come

to a stop without needing to wait for load sway to dampen.

-改進荷重位移的精度。Improves the accuracy of load placement.

-藉著減少潛在個人傷害和設備損害而造成搖擺荷重物碰觸加強操作安全性。

Enhances operational safety by reducing the potential for personnel injuries and damaged

equipment caused by accidental contact with swinging loads.

-藉著減少結構、機械和控制零件的應力減少維修成本。Reduces maintenance costs and

downtime by decreasing stresses on structural, mechanical, and control components.

-減少學習如何處理搖擺荷重所需訓練的時間。

Decreases the training time required to learn how to handle a swinging load.

可撓特性-容易使用 Flexible Features Make It Easy To Use

-可以使用單一或雙重移動的搖擺控制系統。Available in single or dual motion sway control

systems

-使用現有10VAG主開關輸入-24VDC, 24VAC和48VAC輸入為選用(下單時必須先規定)。

Use existing 120VAC master switch sway control systems -24VDC,24VAC, and 48VAC

inputs optional (must be specified at time of order)

-模擬或數位鉤頭高度的回饋輸入附在鉤頭配件之調整。

Analog or digital hook height feedback input with hook attachment adjustments.

-模擬或脈衝訓練搖擺控制頻率參考。Analog or pulse train sway control frequency reference.

-兼容各種變頻器。Compatible with almost any variable speed drive.

-減少85-95%的搖擺 Reduce sway by 85-95%

-Magnetek 材料處理天車功能的好處 Take advantage of Magnetek Material Handling crane

functions

-在無線傳輸或押扣控制可使用或不使用搖擺控制

Enable or disable Sway Control at the radio transmitter or pendant station

2-2.SCS系列2被設計在 SCS Series 2 Has Been Designed To:

-只需要一個脈衝變頻驅動器(VFD),每個行程移動與SCS軟件。額外脈衝變頻驅動連接在

主/副位置。

Require only one IMPULSE Variable Frequency Drive (VFD) per traverse motion with SCS

software. Additional IMPULSE VFDs are connected in a Master/Slave position.

-操作V / F,開式迴路向量和磁通迴路向量的控制方法。

Operate in V/F, Open Loop Vector and Flux Vector* control methods.

-兼容現有的主開關和無線電控制的配置,如 Multi-step 和無限 Variable Uni-polar/Bi-polar模

擬。

Be compatible with existing master switch and radio control configurations such as Multi-

step and infinitely Variable Uni-polar/Bi-polar analog.

-消除需要外部編程邏輯控制器。Eliminate the need for an external programmable logic

controller.

-接受吊鉤高度測量相結合時隨著一個 IMPULSE.VG+系列4起重機驅動。

Accept a hook height measurement when combined with an IMPULSE.VG+ Series 4

hoist drive.

-消除需要高昂的維護反饋設備如絕對編碼器。該系統也可以配置在運轉中吊鉤高度區。

Eliminate the need for a high maintenance feedback device such as an absolute encoder.

The system can also be configured to operate in an operating hook height zone.

-與多個起重機在同一大車上。Work with multiple hoists on the same bridge.

性能特點包括 Performance Features Include:

-選擇輸入用來微調鐘擺長度,當使用多個鉤頭以下配件或不同的負載大小。

Optional inputs available to fine tune the pendulum length when using multiple below the

hook attachments or varying load sizes.

-自動測量吊鉤高度當結合一個IMPULSE.VG+系列4起重機時。

Automatic hook height measurement when combined with an IMPULSE VG+ Series 4

hoist.

-無縫集成,具有特殊功能的IMPULSE變頻驅動器,如微速度和反向的插頭仿真,行程末端減

速,停止限制。

Seamless integration with special functions within IMPULSE variable frequency drives

such as Micro-Speed and Reverse Plug Simulation, end of travel slow down, and stop

limits.

-啟用或停用一個開關翻轉。Enabling or disabling with the flip of a switch.

3.抓斗控制軟件 Bucket Control Software 下載down load

-這種新的訂製軟件可以用IMPULSE.VG+ 系列3驅動器利用裝載/關閉吊車去控制多行翻蓋或抓

鉤抓斗。雖然開放和保持驅動器獨立運行,該軟件可以讓您控制抓斗的各種各樣的活動,而

不需要PLC。

This new custom software can be used with IMPULSE.VG+ Series 3 drives to control

multi-line clamshell or grapple buckets that utilize a loading/ closing hoist. Although the

open and hold drive operate independently , the software lets you control the various

motions of the bucket without the need for a PLC.

-設有抓斗位置指示,提供操作者隨著抓斗的打開/關閉狀態,當正在挖泥(水下)或當看不見

抓斗。這是從關閉吊車通過模擬輸出和從模擬儀表上接收到,或由MMI。

It features Bucket Position Indication, providing the operator with the open/close status of

the bucket while dredging (underwater) or when the bucket in not visible. This is done via

analog output from the closing hoist and is received by an analog meter , or by an MMI.

-無通訊(如主/從)是必要的!為了維持在打開位置,而抓斗降低,這兩個吊車必須以相同的

速度運行。為了要保持一個全關閉的抓斗,而提高了抓斗,兩吊車之間的扭矩必須按比例分

擔。

No communication (such as master/slave) is needed! In order to maintain the bucket in

the open position while lowering, both hoists must operate at the same speed. In order to

keep a full bucket closed while raising it out of the pile, torque must be proportionally

shared between the two hoists.

同步驅動軟體 Drive Synchronization software

我們的定制軟件可以讓你同步多個IMPULSE.VG+系列3驅動器。該“副”驅動器利用一個編碼器

選項板輸入兩個

編碼器,並監測其本身的編碼器反饋和“主”編碼器反饋,同時也發送定時狀態信息回主編碼

器。副編碼器對任何

位置誤差進行補償,通過調整電機轉速,在主機和副機的電機軸之間近乎完美對齊。副驅動器

也具有自動重新

同步電機的能力,並具有電子齒輪功能。雖然這兩個驅動器都在運行,有沒有位置誤差的積

累,因此對齊始終保持。

Our custom software allows you to synchronize multiple IMPULSE.VG+ Series 3 Drives.

The“slave” drives

utilize an encoder option board with two encoder inputs , and monitor both its own encoder

feedback AND the

“master’s” encoder feedback , while also sending timing status information back to the

master. The slave

compensates for any position errors by adjusting its motor speed resulting in near-perfect

alignment between

the master and slave motor shafts. The slave drive also possesses the ability to

automatically re-synchronize

the motors, and has an electronic gearing feature. While both drives are running, there is

no accumulation of

position error, so alignment is always maintained.

1-5.抓斗控制軟體BUCKET CONTROL SOFTWARE

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 ...

1-4.變頻器同步軟體DRIVE SYNCHORIZATION SOFTWARE

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 ...

1-3.腳踏剎車/靜止無段式模擬軟體FOOT BRAKE / STATIC STEPLESS SIMULATION SOFTWARE

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 ...

1-2.防止搖晃控制系統(SCS) S2 SWAY CONTROL SYSTEM (SCS) SERIES 2

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 ...

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 IMPULSE G+/VG+ SERIES 3 DRIVES CUSTOM SOFTWARE APPLICATIONS

1.IMPULSE G+/VG+ S3變頻器-客戶使用軟體的應用 ...